Şirketimiz hafif silah mühimmatı montaj hatları üretimi yapmaktadır.

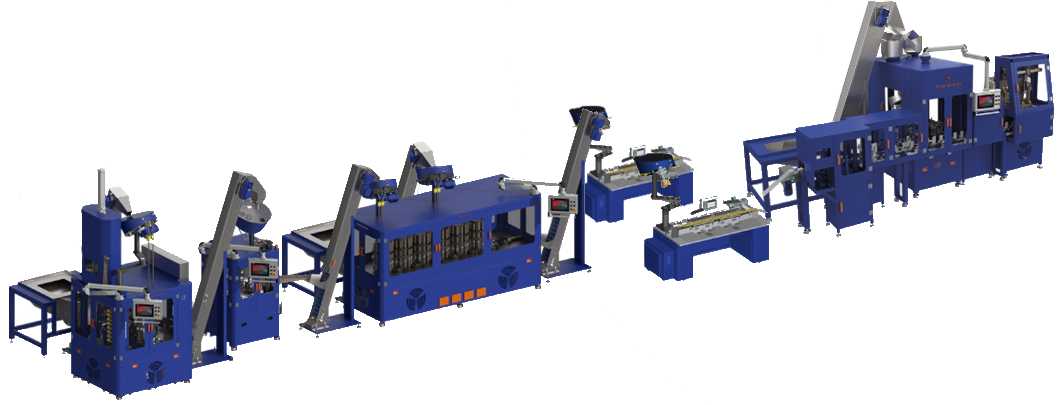

The ammunition assembly line is a high-capacity, multi-caliber system designed for assembling small arms military ammunition, including pistol and rifle calibers. It requires minimal manpower and complies with the ATEX Directive, making it Ex-proof (explosion-proof).

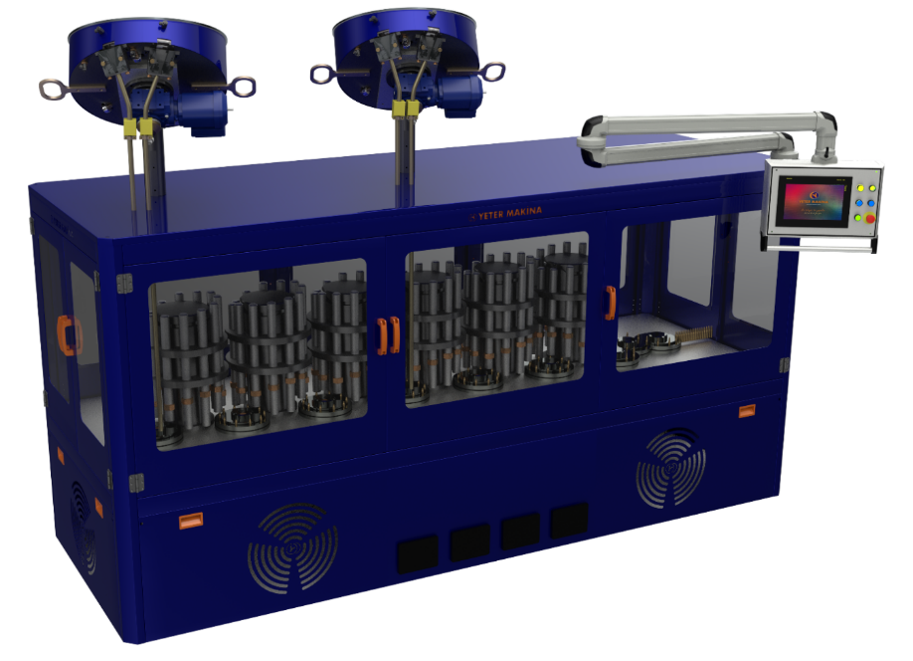

Primer inspection. Checks for right-side-up primer and the existence of primer anvil. • Cartridge case inspection. Checks for the flash hole, extractor groove, and cartridge mouth circularity. (Checking for the flash hole also assures that only empty primer pockets are inserted with primer) • Ring crimping (Ring-crimp or 3-stab crimping based on customer’s preference) • Ring-crimp inspection. Camera check for the existence of ring crimping. • Primer depth inspection. Checks for accurate depth of primer. • Sound and safety enclosure • Dynamic, continuous primer insertion • Door-closed sensors

Cartridge mouth circularity assurance • Avoiding varnishing the faulty shell cases saves on sealant and protects the needle inside the cartridge mouth when applying the sealant. • No cartridge case, no dispense. A ‘Case existing check’ is performed to prevent sealant from spilling inside the machine. If the case does not exist on a certain station the needles do not apply sealant. • No primer, no dispense. If the case is missing the primer, it will be discharged. • Sealing around the primer and inside the case neck at the same time • Sound and safety enclosure • Easy operation through HMI touch screen. • Dynamic, continuous sealant application • Door-closed sensors • Buffer area for curing • Durable framework.

• Case existing check • Cartridge mouth circularity check (Discards if faulty) • Gunpowder existing (Discards if faulty) • Gunpowder level check (Discards if faulty) • Bullet feeding and seating • Bullet existing check (Discards if faulty) • Bullet leveling and mouth crimping • Cartridge length check (Discards if faulty) • Cartridge exterior form/loadibility check. (Discards if faulty) • High-accuracy dynamic check-weight station. (Discards the faulty) • The real-time production count is displayed on the HMI screen. • Sound and safety enclosure • Dynamic, continuous loading • Door-closed sensors • Durable framework

• Boxes folded and glued automatically. • Camera check for box folding (discards if faulty) • Rifle cartridges are stacked into boxes in alternating order. Pistol cartridges are filled in plastic trays first, and then placed in boxes. • Box closing and hot gluing. • Camera check for box closing (discards if faulty) • Weight check for quantity (discards if faulty)